Location:Home > Products > High temperature

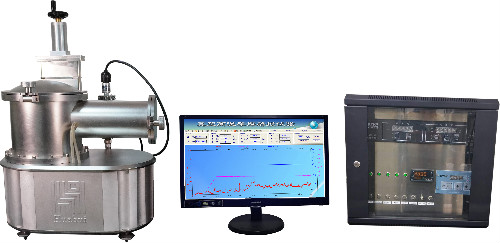

MS-VHT1200 High-Vacuum and Temperature Friction Wear Tester can be used for the evaluation of the high temperature friction and wear performance of various materials and films under vaccum and different special gas ambient.

(Test curve)

This tester uses the ball-on-disk friction principle, the technology of program temperature control system and Vacuum pumping system technology.At the same time, the sample is fixed on the test platform under the high temperature environment and rotates at a certain speed to make the surface of the ball friction coating.The friction coefficient curve and temperature setting curve can be obtained by calculating the friction signal obtained from the sensor, amplified and processed by the input computer through A / D conversion.

μ=F/N

μ—friction coefficient

F—friction force

N—normal load

Through the change of friction coefficient curve and temperature setting curve, the friction performance and wear resistance of materials or thin molds in vacuum or special atmosphere at high temperature are obtained. under a specific load, after a certain time (certain distance), the friction coefficient will be changed, in that moment, the film is worn out and the wear volume will be obtained by the weighing method.

Key technical parameters

1. Instrument weight:80kg

2. Appearance size:600×350×550(mm×mm×mm)

3. Power:4.5kw

4. Operating Voltage:220V

6. Vacuum pumping mode: direct molecular pump

7. Maximum temperature:1100℃

8. Rated temperature: room temperature ~1000℃ Multi-stage program setting

9. Heating rate: <10℃/min

10. .Load mode:Weight loading

11. Load:100~2000g

12. Friction measurement range:0~10N the accuracy is 0.15% F.S

13. Friction coefficient accuracy: < 0.01

14. Stage rotation speed: 10~1000 r/min,the accuracy is ±1 r/min

15. Rotation radius: 3~15 mm

16. Can be flushed into auxiliary gas to achieve high-temperature friction experiments in special atmosphere environments

17. Mating materials diameter: Φ4 mm, Φ6 mm

18. Friction pair materials: GCr15 steel ball, AlO ceramic ball, ZrO ceramic ball, SiN ceramic ball

19. Sample size:Φ52mm Thickness:1~7mm(Φ 20-52mm samples can be designed with fixtures to achieve measurement of samples of different specifications)

20. Data processing: the Access, Excel database file, Word experiment report and Jpeg picture can be generated