Location:Home > Products > Current carrying

This tester can be used for the evaluation of the friction and wear performance of various materials and films. It can also be applied for detecting the static electricity on line and friction performance under oil and grease base lubrications (accessories required).

(Test curve) (High temperature test curve)

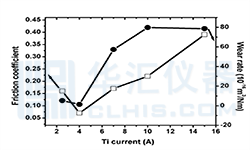

(Electrostatic test curve) (Analysis curve)

(Electrostatic full picture) (Contact form)

Key technical parameters

1. Instrument weight:33kg

2. Appearance size:330×210×370(mm×mm×mm)

3. Load mode:Weight loading

4. Load:100~2000g

5. Friction measurement range:0~10N the accuracy is 0.15%F.S

6. Stage rotation speed:10~3000 r/min, the accuracy is ±1r/min

7. Stage height variation range:0~20mm

8. Rotation radius:3~20 mm

9. Power:1kw

10. Operating Voltage:220V

11. Sample size:Φ10~Φ53mm thickness:1~10mm

12. Mating materials diameter:Φ3mm, Φ4mm, Φ5mm, Φ6mm

13. Friction pair materials:GCr15 steel ball, AlO ceramic ball, ZrO ceramic ball, SiN ceramic ball

14. Data processing:the Access, Excel database file, Word experiment report and Jpeg picture can be generated

Optional:

1. Load range:

Weight loading:10~100g

Small range:Weight loading:1~10g

2. Friction force range:

(1)Medium range:0~1N the accuracy is 0.15%F.S

(2)Small range: 0~0.1N the accuracy is 0.15%F.S

3. Heating components: room temperature to 200℃, Multi-stage program setting

4. Vacuum measurement accessories:-0.08MPa~the atmospher

5. Static measurement accessories

(1) measurement range:0~±2000V

(2) Display resolution:±1/2000,Minimum display resolution up to 1V

(3) Accuracy:better than2%, reading ±1digit

(4) Quality:2KG

(5) Power:220VAC50Hz<10W

(6) Working environment:0~40℃,90%RH

6. Current-carrying friction components

(1) Testing friction current:5A

(3) Dynamic in-situ and synchronous real-time friction coefficient measurement

(4) Dynamic in-situ, synchronous, real-time friction current test

(5) Dynamic in-situ, synchronous, real-time friction coefficient, and friction current display

7.electrochemical corrosion module

Hardware specifications:

Constant potential control range of friction corrosion: ± 10V

Constant current control range of friction corrosion: ± 200mA

Control accuracy of friction corrosion potential: 0.1% × Full scale reading ± 1mV

Control accuracy of friction corrosion current: 0.1% × Full scale reading

Friction corrosion potential resolution: 10uV (>100Hz), 3uV (<10Hz)

Friction corrosion current sensitivity: 1pA

Friction corrosion current range: 2nA~200mA, 9gears in total

Friction corrosion tank pressure: ± 13V

Maximum output current of friction corrosion: 200mA

Frequency response of friction corrosion impedance: 10uHz~1MHz

Functions of electrochemical corrosion software:

Open circuit potential test (OCP), potentiostatic polarization, constant current polarization, linear cyclic voltammetry (CV), linear scanning voltammetry (LSV), square wave voltammetry (SWV), polarization curve test (Tafel), battery charge discharge test (GCD), impedance test

The software supports the serialization test function, and can realize automatic measurement under unattended condition through user-defined method combination;