Location:Home > Products > Heavy haul series

This tester is designed for the evaluation of the high temperature (room temperature to 600 ℃) friction and wear performance of diverse layered solid lubrication materials, films, metals as well as ceramic materials under the simulated environments of aerospace and aviation. This tester can achieve a wide range variation of load and friction speed, realizing the evaluation of the relationship between PV values and tribological properties of a material.

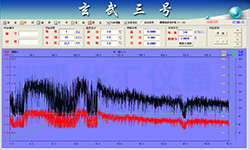

(Test curve) (wear scar)

This tester is used to test the friction between the bolt-on-disk and the disk-on-disk under high temperature and heavy load, and to detect the change of friction coefficient of materials.And uses the ball-on-disk friction principle, the technology of program temperature control system and Vacuum pumping system technology.At the same time, the sample is fixed on the test platform under the high temperature environment and rotates at a certain speed to make the surface of the ball friction coating.The friction coefficient curve and temperature setting curve can be obtained by calculating the friction signal obtained from the sensor, amplified and processed by the input computer through A / D conversion.

μ=F/N

μ—friction coefficient

F—friction force

N—normal load

Through the change of friction coefficient curve and temperature setting curve, the friction performance and wear resistance of materials or thin molds in high temperature and high load are obtained. under a specific load, after a certain time (certain distance), the friction coefficient will be changed, in that moment, the film is worn out and the wear volume will be obtained by the weighing method.

Key technical parameters

1. Instrument weight:520kg

2. Appearance size:800×740×1540(mm×mm×mm)

3. Test temperature: room temperature~600 ℃ multi-step heating stage

4. Load:1~100 kg

5. Shaft rotation speed: 10~1500 r/min, accuracy ±1 r/min

6. Friction coefficient accuracy:1%F.S

7. Stage size: 45 mm

8. Friction bolt diameter: 2~4 mm

9. Fiction rotation radius: 10mm, 15 mm, and 20 mm

10. Stage height variation range: 0~50 mm

11. Power:6kw

12. Operating Voltage:220V

13. Data processing: the Access, Excel database file, Word experiment report and Jpeg picture can be generated