Location:Home > Products > Electrochemical corrosion

MS-ECT3000 Rotary Electrochemical Corrosion Friction Wear Tester is designed for evaluating the rotating friction and wear performance of materials and films running in corrosive solutions with variation of load and rotating speed. It is mainly used for the measurement of the friction and wear measurement under corrosive solution, mainly simulating the conditions of sea, river, lake, and body fluid.

Friction properties and abrasion resistance of the material or film will be obtained through the change of the friction coefficient curve, i.e., under a specific load, after a certain time (certain distance), the friction coefficient will be changed, in that moment, the film is worn out and the wear volume will be obtained by the weighing method.

Electrochemical workstation test components include the electrochemical workstation and liquid tank. The sample is put into the sample vessel and the electrochemical changes in the friction process will be detected through the working electrode (the underneath counterpart as contact electrode) and the reference electrode.

The high-temperature friction and wear test can be conducted by heating the sample (or tank) with a set temperature.

The controlled atmosphere components extract gas through vacuum pumps and gases(N2、He and etc.) are passed in so that samples could be tested in different atmospheres.

The section area of wear scar will be obtained directly by measuring the wear depth using the detection component of the wear loss.

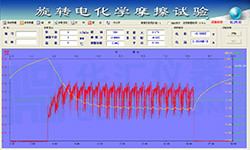

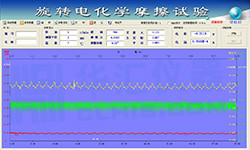

(Test curve)

Key technical parameters:

1.Instrument weight:33kg

2.Appearance size:330×210×370(mm×mm×mm)

3.Loading way:Weight loading

4.Loading:100~2000g

5.Friction measurement range:0~10N

6.Friction measurement accuracy:0.25%F.S

7.Stage rotation speed:1~3000 r/min, accuracy±1r/min

8.Rotation radius:5~10 mm

9.Electrochemical test Rotating speed:1~200 r/min, accuracy±1r/min

10.Stage height variation range:0~20mm

11..Power:2kw

12..Operating Voltage:220V

13.Sample size:Φ48±0.3mm,The thickness is 1~5mm

14.Electrochemical module: A set of rotating modules made of polytetrafluoroethylene or nylon, including an electrochemical corrosion-resistant tank, electrode clamping components, and an electrochemical workstation connection part

15.Electrochemical workstation test components:

l Hardware specifications:

Constant potential control range of friction corrosion: ± 10V

Constant current control range of friction corrosion: ± 200mA

Control accuracy of friction corrosion potential: 0.1% × Full scale reading ± 1mV

Control accuracy of friction corrosion current: 0.1% × Full scale reading

Friction corrosion potential resolution: 10uV (>100Hz), 3uV (<10Hz)

Friction corrosion current sensitivity: 1pA

Friction corrosion current range: 2nA~200mA, 9gears in total

Friction corrosion tank pressure: ± 13V

Maximum output current of friction corrosion:200mA

Frequency response of friction corrosion impedance: 10uHz~1MHz

l Functions of electrochemical corrosion software:

Open circuit potential test (OCP), potentiostatic polarization, constant current polarization, linear cyclic voltammetry (CV), linear scanning voltammetry (LSV), square wave voltammetry (SWV), polarization curve test (Tafel), battery charge discharge test (GCD), impedance test potential/current control mode, constant frequency impedance test potential/current control mode, Motschottky curve test;

The software supports the serialization test function, and can realize automatic measurement under unattended condition through user-defined method combination;

16.Mating materials diameter: Φ4 mm, Φ5 mm, Φ6 mm

17.Friction pair materials: GCr15 steel ball, AlO ceramic ball, ZrO ceramic ball, SiN ceramic ball

18.Data processing: the Access, Excel database file, Word experiment report and Jpeg picture can be generated

19. Load range:weight load Medium range: 10~100g Small range: 1~10g balancing

20. Friction force range:Medium range: 0~1N Small range: 0~0.1N