Location:Home > Products > Electrochemical corrosion

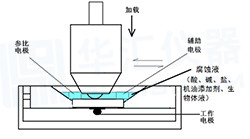

MFT-EC4000 Reciprocating Electrochemical Corrosion Friction Wear Testeris mainly used to simulate the corrosion and friction state of materials in the sea, lakes, rivers and oil and gas drilling and production. It aims at quantitative evaluation of the friction performance, corrosion performance and wear resistance of the material surface and film under different loads, frequencies, temperatures and atmospheres in the form of high-speed reciprocating operation in the corrosive medium.

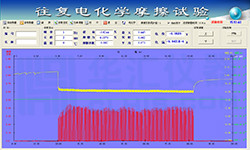

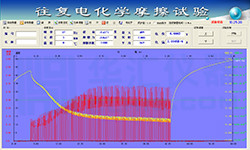

(Electrochemical corrosion curve) (Electrochemical corrosion curve)

(Wear curve) (Electrochemical corrosion friction)

(Constant Loading Curve) (Sinusoidal loading curve)

(Triangular loading curve) (Gradient loading curve)

Key technical parameters:

1. Instrument weight:42.5kg

2. Appearance size:400×250×360(mm×mm×mm)

3. Loading way:

Weight loading

Automatic loading:constant loading、Alternating loading (sine wave loading, triangle wave loading, gradient loading)

4. Loading range:

Weight loading:500~2000g

Automatic loading:0~300N the accuracy is 0.25%F.S

5. Friction measurement range:0~100N, the accuracy is 0.25%F.S

6. Reciprocating frequency: 0.05~20Hz

7. Reciprocating times: not limited

8. Lift height: 20mm

9. Reciprocating distance: 2.5 ~ 40mm

10. Sample size:Φ53±0.5mm,The thickness is 1~5mm

11. Mating materials diameter: Φ4 mm, Φ5 mm, Φ6 mm

12. Friction pair materials: GCr15 steel ball, AlO ceramic ball, ZrO ceramic ball, SiN ceramic ball

13. Power:2kw

14. Operating Voltage:220V

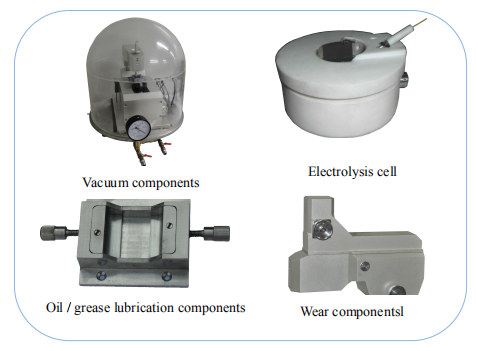

15. Electrochemical corrosion module bench

16. Electrochemical corrosion component interface

17. Electrochemical workstation test components:

l Hardware specifications:

Constant potential control range of friction corrosion: ± 10V

Constant current control range of friction corrosion: ± 200mA

Control accuracy of friction corrosion potential: 0.1% × Full scale reading ± 1mV

Control accuracy of friction corrosion current: 0.1% × Full scale reading

Friction corrosion potential resolution: 10uV (>100Hz), 3uV (<10Hz)

Friction corrosion current sensitivity: 1pA

Friction corrosion current range: 2nA~200mA, 9gears in total

Friction corrosion tank pressure: ± 13V

Maximum output current of friction corrosion:200mA

Frequency response of friction corrosion impedance: 10uHz~1MHz

l Functions of electrochemical corrosion software:

Open circuit potential test (OCP), potentiostatic polarization, constant current polarization, linear cyclic voltammetry (CV), linear scanning voltammetry (LSV), square wave voltammetry (SWV), polarization curve test (Tafel), battery charge discharge test (GCD), impedance test potential/current control mode, constant frequency impedance test potential/current control mode, Motschottky curve test;

The software supports the serialization test function, and can realize automatic measurement under unattended condition through user-defined method combination;

18.Key components: sliding table: America; Reciprocating motor: Japan; Loading motor: Germany

19.Test operation: keyboard operation, microcomputer control

20.Data processing: the Access, Excel database file, Word experiment report and Jpeg picture can be generated

21.Optional:

l Load range:

Medium range:Weight loading:100~1000g

Automatic loading:0~30N the accuracy is 0.25%F.S

Small range: Weight loading:10~100g

l Friction force range:

Medium range:0~10N the accuracy is 0.25%F.S

Small range: 0~1N the accuracy is 0.25%F.S

l Wear measurement components

(1) Moving range:2~10mm

(2)Measurement range: 1 ~ 200μm

(3) Accuracy: 0.1μm

(4) Indenter: diamond with 90°cone angle, the tip radius is 0.1mm