Location:Home > Products > Low temperature series

FCT-4000 Ultra-low Temperature (superconducting) Friction Wear Tester is designed for the evaluation of the friction and wear performance of a material under the simulated environments of aerospace, aviation and ultralow temperature. Particularly, it can be used for evaluating the friction and wear behaviors of metal alloys and ceramic composites under different gas ambient with temperature variation from -180 to 100 ℃.This tester can work in (ball)-disc mode under dry friction as well as with or without solid lubrication conditions.

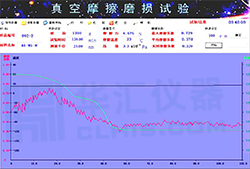

The tester uses a vacuum pump to vacuum the vacuum environment laboratory, remove unnecessary gases and moisture, and then uses liquid nitrogen to reduce the temperature of the vacuum laboratory to below - 180 ℃. At low temperature, through the magnetic transmission technology, the friction experiment between bolts (balls) - disks is realized, and the change of friction coefficient of materials is detected. By using the computer control technology, the load is added to the bolt (bead) through the weight loading mechanism, which acts on the surface of the sample. At the same time, the sample is fixed on the test platform, and rotates at the set speed. The friction signal is obtained through the sensor. After amplification, the input computer obtains the friction coefficient curve through the calculation of the friction signal through the A / D conversion. Through the change of friction coefficient curve, the tribological characteristics of various materials at low temperature are obtained.

(Test curve) (Operation panel) (Contact form)

Key technical parameters

1. Instrument weight:290kg

2. Appearance size:680×710×1000(mm×mm×mm)

3. Size of Chamber: Φ400mm × 400mm

4. Test temperature: -180~100℃

5. Ultimate vacuum: <10-4Pa

6. Load: 1500~5000g

7. Rotating speed: 10~3000 r/min

8. Rotation radius: 3~20 mm

9. Accuracy for dynamic friction coefficient: 1%F.S

10. Stage size: 70 mm

11. Stage height variation range: 0 ~ 25 mm

12. Mating materials diameter: Φ3 mm, Φ4 mm, Φ5 mm, Φ6 mm

13. Power:7kw

14. Operating Voltage:220V

15.Data processing: the Access, Excel database file, Word experiment report and Jpeg picture can be generated